数控机床英文翻译

标签:液压数控机床 2025-10-27 03:59:43 91次

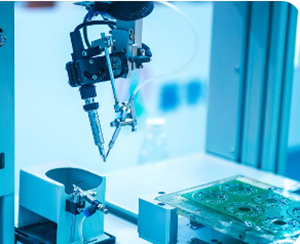

Possible article:Title: Advances in CNC Machine Tools for Manufacturing 4.0In 2023,数控金华数控折弯机 the global market for computer numerical control (CNC) machine tools is expected to exceed $100 billion, driven by the growing demand for precision machining and automation in various sectors, such as aerospace, automotive, medical devices, and electronics. However, the industry also faces several challenges and opportunities related to technology innovation, workforce development, sustainability practices, and global competition. Here are some of the main themes that shape the current state and future prospects of CNC machine tools.1. Smart control systemsOne key trend is the adoption of intelligent controls that enable real time monitoring and optimization of machining performance. This requires integrating sensors, data analytics software, artificial intelligence algorithms, and cloud connectivity into CNC machines. The benefits include higher accuracy rates, faster cycle times, lower energy consumption levels,and proactive maintenance planning based on predictive models.Possible solutions: Develop open source platforms for sharing sensor data across different brands of machine tools Collaborate with universities or research institutions to design custom algorithms for specific tasks or materials Provide training programs or certifications for operators who can interpret sensor feedback and adjust parameters accordingly2. Additive manufacturing integrationAnother trend is the convergence between subtractive machining processes (such as drilling,cutting,sanding)and additive techniques(such as 3D printing,laser sintering). By combining these methods within a single CNC system,the user can create more complex geometries with less material waste,reduced lead times,and improved quality standards.This also opens up new possibilities for repairing,duplication,mold making,and customization applications.Possible solutions: Invest in R&D projects that test novel materials,powders,resins,and hybrid toolpaths Establish partnerships with startup companies or industry leaders who specialize in additive manufacturing services or hardware integrations; Explore vertical markets where additive technologies have shown strong potential,such as biomedical implants, aerospace components, and architectural models.3. Human machine collaborationA third trend is the emphasis on designing more ergonomic,cognitive,and user friendly interfaces between CNC machines and human operators. This involves not only improving the software interface but also considering factors such as job satisfaction, skill development,and safety risks.The goal is to create a seamless interaction that maximizes both labor efficiency and creativity.Possible solutions: Conduct surveys or interviews with machine operators to identify pain points or suggestions for interface improvements; Use virtual reality(AI)or augmented reality(AR)systems to simulate different scenarios where users can test new interfaces without risking real damage; Recruit employees from diverse backgrounds (such as artists,dancers,musicians)and apply their skills in designing visual or auditory elements that enhance the user experience.